Our Services

- Installation and Maintenance of High Voltage/Low Voltage Electrical Distribution System.

- Installation and Maintenance of General Electrical System in Building, inclusive of:

- HV/LV Electrical System

- Generator Set/Pumping System

- Motor Overhaul/Servicing/Maintenance and Rewinding

- Plant Lighting

- Installation of Cable Trays and Ladders

- Installation of Electrical Equipment and Cable Laying

- Actuator Installation & Commissioning of MOV (Motor Operated Valve)

- Installation, Full Audit Survey, Closed Interval Potential Survey (CIPS) and Commissioning of Cathodic Protection System

- Design, Installation and Maintenance of Fire Protection System.

- Fire Alarm

- Gas Detector

- Installation and Maintenance of Plant Instrumentation.

- Transmitters

- Control Valves

- DCS/PLC

- Analyzers

- CCTV/MATV System

- Tubing and Airline System

- Design, Installation and Maintenance of HVAC.

- Other Process, Mechanical and Electrical & Instrument Design and Installation.

- Plant Maintenance and Turnaround Services.

- Oil Cleaning and Filtration Services.

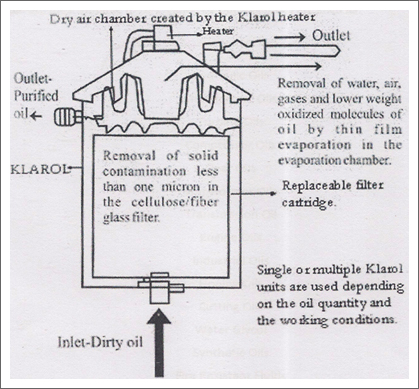

A mobile oil cleaning system is capable of keeping your oil at better-than-brand-new-oil cleanliness. This machine works with the industry that majors in automotive to injection moulding to huge turbines. The oil cleaning system is capable of removing less than 0.25 micron sized particles, 100 percent of moisture, air and gases from hydraulic oils, turbine oils, lube oils, gear oils, biodiesel and testing oils.

Use depth filtration and evaporation to restore dirty oil and maintain it better than new oil.

The product is build and designed to clean oil in two stages using three different methods. In the beginning oil enters the machine in depth filter to be cleaned by going through absorption. During the process, all solid contaminants up to five microns are removed in this stage.

The oil then pass at a controlled flow rate into the machine's evaporation chamber which is heated. It is to ensure a dry airspace. In controlling the flow oil through machine guarantees the formation of thin oil film in the evaporation chamber. These conditions are ideal to evaporate moisture, lower oxidized molecules of oil, air and gases from the oil. Purified oil then goes back into the main tank that oil has come from.

- Hydraulic Oils

- Transformer Oils

- Turbine Oils

- Compressor Oils

- Gear Oils

- Transmission Oils

- Engine Oils

- Industrial Oils

- Cutting Oils

- Honing Oils

- Water Glycol

- Synthetic Oils

- Fire Resistant Fluids

- Kerosene Oil & any others

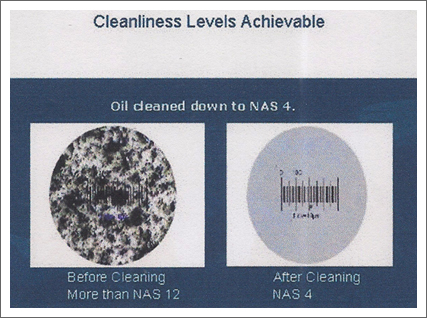

Researches have shown in cleanliness level that the machines can produce. Oil Cleaning System can purify oil down to NAS 4, from more than NAS 12. They are capable of removing sludge, varnish and lacquer from all oils. These systems can also remove emulsified water from all oil down to less than 50 p.p.m.

LEVEL OF REMOVING OIL CONTAMINATION

As seen in the above chart, this proves the cleanliness level that is achievable that the machine can produce. This tests the method of testing contamination in mineral oils.

The picture on left of the membrane is prove of after the oil passes through is studied under a microscope and compared to pre-determined patches provided in a color chart. The comparison can help us to determine the ISO Value which is the level of cleanliness of the sample oil.

This value can be co-related to equivalent NAS Value. The machines can clean oil as dirty as with NAS Value more than 12, down to as clean as with NAS Value 4.

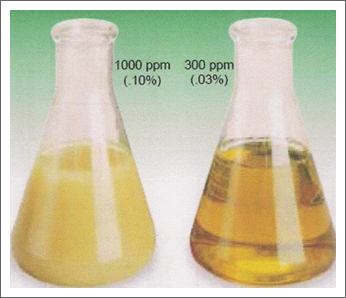

CAPABILITY OF THE MACHINE FROM REMOVING WATER

Mobile oil cleaning machine installed permanently on oil tanks with pre-heater and vacuum pump can remove considerable water contamination from hydraulic on turbine oils. We have in some places cleaned hydraulic oils or turbine oils with 20,000 p.p.m of water down to less 50 p.p.m of water.